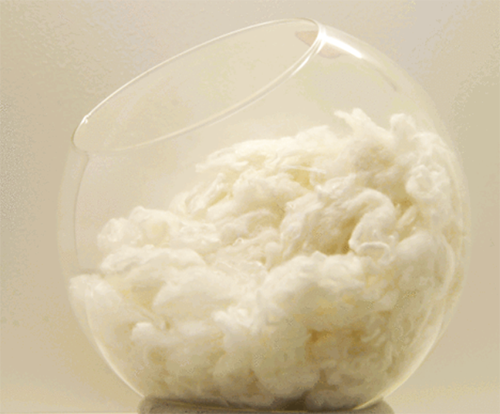

Natural Viscose Fiber

Viscose fiber is made of natural fiber (wood fiber, cotton short velvet) as raw material, through alkalination, aging, sulfonation and other processes to make soluble cellulose sulfonate, then dissolved in dilute lye to make viscose, and made by wet spinning. A large number of chemical additives are used in the production process, which is the most original recycled fiber and the first generation of recycled fiber.

Viscose fiber can be divided into ordinary viscose fiber, high wet modulus viscose fiber, strong viscose fiber and modified viscose fiber.

The complex preparation process of viscose fiber makes the cross section of the fiber filaments be waist round or irregular, with internal holes and longitudinal grooves without rules.

Viscose fiber has good hygroscopic property, under general atmospheric conditions, moisture regain rate of about 13%, in line with the physiological requirements of human skin. Fabric soft, smooth, good air permeability, not easy to static electricity, comfortable to wear. The disadvantages are low wet modulus, high shrinkage rate and easy deformation, obvious expansion after moisture absorption, the diameter can be increased by 50%, the fabric feels hard after encountering water, and the elasticity and wear resistance are poor.

Viscose fiber can be pure spun, can also be blended with other fibers, suitable for all kinds of clothing fabrics and decorative supplies. Filament fabric is light in texture, which is not only suitable for clothing fabrics but also for bedding and decorative supplies.

Related News

Submitted successfully

We will contact you as soon as possible